BCP Series Flexible Bending Solution

The BCP seamlessly integrates productivity through its automated bending and handling processes and versatility via its universally adaptable bending tools.

Customer Value

-

Combine productivity and flexiibility, fully automatic and easy operation

-

Automatically fold up and down to realize the bending of circular arc, flattening and positive/negative various angles

-

Min. loading and unloading impact on total cycle time

-

Smart program set-up linkage between manipulator and blankholder

-

Free re-tooling during operation, only need to change blankholder when change part

-

15axis linkage control, 3 axis fully automatic positioning system

-

Full servo control, low energy consumption

-

0.2 seconds/bend, free re-tooling

-

Oil supply self-lubricating system,automatic alarm for oil shortage

Intelligent system

-

INSERTER independent intellectual property operating system

-

Sino German cooperative development system with 3D animation bending demonstration to visualize the bending process

Flexible automation

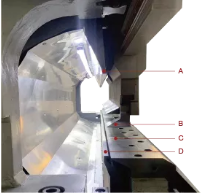

Upper and lower blade, counter blade and blankholder are the four universal tools used to process the whole range of thicknesses and machinable materials, from 0.3 to 3.0 mm.

|

The upper and lower blades (A, D) are the two tools featuring interpolated controlled movement and responsible for bending. The automatic blankholder (B) works simultaneously with the blades and counterblade to bend and clamp the sheet accurately and effectively. The counterblade (C) helps clamp the sheet during the cycle |

Automatic pressure arm: fast and accurate

Quickly and fully automatically, press arm moves, handles, grips and rotates the sheet metal throughout the whole machining cycle.

Operating mode: simple quick

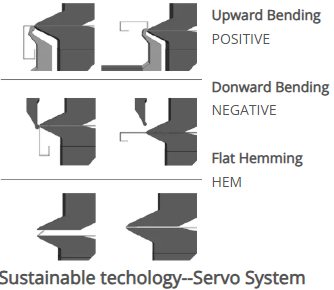

A combined automatic mold system can achieve various processes such as upward bengding,downward bending, flat hemming,ect.

Sustainable techology--Servo System

The panel bender we have developed adopts a relatively advanced fully electric servo closed-loop system.which can achieve multi axis linkage. The bending action is smooth and smooth, and the mechanical action coordination is high.lt can easily achieve various complex bending action combinations, and the overall work efficiency and bending accuracy are leading in China.

It adopts only electric actuators, thus removing the hydraulics. Bending cylinders are driven by brushless motors, which offers great advantages in terms of the reduced wear and deterioration of components that, unlike in other similar technologies, are no longer subjected to continuous extreme mechanical stress.

Production diversity--Custom solutions

Customized Hinge Tool: Mechanical hinge tool/Rneumatic hinge tool Servo hinge tool

Auxiliary Bending Tool:Two servo motors drive both ends of the local tool, the system according to the plate bending programming requirements, automatic use of local tool, so that one-sided local bending of the plate becomes a reality, enrich the bending style

Positioning system--Automatic positioner

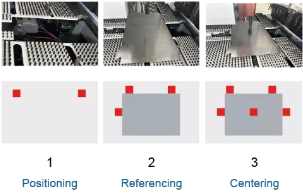

The product positioning just once at the start of the process, against controlled mechanical stops: the cycle time is minimized and any precision errors are all absorbed by the first bend.

|

The product positioning just once at the start of the process, againstcontrolled mechanical stops: the cycle time is minimized and any precision errors are all absorbed by the first bend. The five-axis positioning system removes the bending accuracy deviation caused by manual positioning errors. |

Technical parameter

Inserter offers different models, which bend up to 3000 mm in length and 170mm in height, responding to all production needs and maximizing use of the panel bender.

Sipariş Formu